Clear vinyl is an excellent material for creating stencils in the screen printing process, particularly when combined with photo emulsions. This method is ideal for detailed designs, as it allows for sharp and precise prints. Below is a comprehensive overview of how to use clear vinyl in screen printing with emulsion and why it’s a great choice for certain projects.

What is Clear Vinyl in Screen Printing?

Clear vinyl is a thin, transparent material often used as a stencil in screen printing. It is applied to a screen coated with emulsion to create a design template. The transparency of clear vinyl allows for accurate placement and precise cutting of designs, making it a preferred choice for intricate artwork. When exposed to UV light, the emulsion hardens around the vinyl, leaving the design areas clear and ready for ink application.

Also Read N: Understanding AMC A-List Membership And What It Offers

Benefits of Using Clear Vinyl for Emulsion in Screen Printing

- Precision and Detail: Clear vinyl allows for high-precision cuts and detailed designs, making it ideal for fine text and intricate artwork.

- Easy Placement: Since clear vinyl is transparent, it’s easier to align designs accurately on the screen, ensuring that every print is perfectly positioned.

- Durability: Vinyl stencils can withstand multiple uses, allowing you to print repeat designs without degradation.

- Compatibility with Various Inks: Clear vinyl works well with a variety of ink types, including solvent-based, water-based, and UV inks, making it versatile for different substrates.

Also Read P: Having A Gap Crossword: Understanding The Clue

Step-by-Step Process for Using Clear Vinyl with Emulsion

- Coat the Screen with Emulsion: Begin by applying a layer of emulsion onto the screen. Ensure the coating is even and allow it to dry in a dark environment to prevent premature exposure.

- Prepare the Vinyl Stencil: Use a vinyl cutter to create your stencil. Place the clear vinyl carefully onto the screen, aligning it with the areas where you want the ink to pass through.

- Expose the Screen: Once the vinyl is in place, expose the screen to UV light. The areas covered by vinyl will remain soft, while the exposed emulsion hardens, creating a stencil of your design.

- Wash Out the Screen: After exposure, rinse the screen with water. The unexposed emulsion will wash away, leaving a clear template for printing.

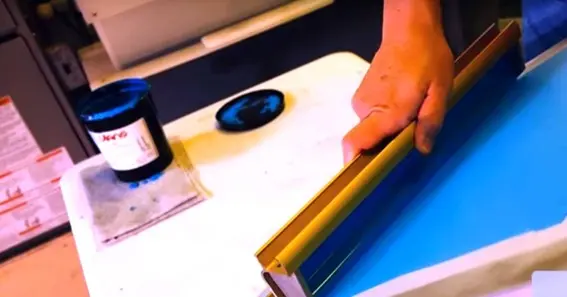

- Start Printing: With the stencil ready, you can proceed to apply ink using a squeegee. The stencil created by the vinyl will direct ink only to the intended areas, ensuring crisp prints.

FAQ

1. What type of clear vinyl is best for screen printing?

Opt for a thin, clear vinyl with good adhesion properties to ensure it stays in place during exposure. Removable clear vinyl is often recommended for easy repositioning.

2. Can I reuse vinyl stencils for multiple prints?

Yes, clear vinyl stencils are durable and can be reused for multiple prints, especially when applied and removed carefully.

3. What emulsion should I use with clear vinyl?

Dual-cure and photopolymer emulsions are popular choices due to their durability and precise exposure capabilities. Make sure to choose an emulsion compatible with the type of ink you’re using.

4. How long does it take for the emulsion to harden during exposure?

Exposure times vary based on the emulsion type, the UV light intensity, and the screen’s mesh count. Typically, it takes a few minutes; follow the emulsion manufacturer’s guidelines for optimal results.

5. Is clear vinyl suitable for all screen printing applications?

Clear vinyl is ideal for detailed designs and repeat prints, but for very large-scale designs, traditional emulsion-only methods might be more efficient